Working with gas equipment is a complex procedure that requires a careful and responsible approach. The installation of a gas stove should ideally be carried out by specialists from a service company.

Where to go to connect a gas stove in a house or apartment

Kitchen equipment is replaced during apartment renovation or if there are faults in the units. You can connect a gas stove at home yourself, but it is advisable to do this with the help of specialized specialists, although not everyone knows where to go to receive the appropriate service.

Where to look for a gas technician

When selling gas kitchen equipment, many stores additionally offer the service of professionally connecting the stove to the gas supply. This is the option that many buyers use. Otherwise, you can contact other specialists.

- Find out who is servicing gas appliances, if we are talking about an apartment building, and order work from specialists from the relevant company.

- Contact a specialized organization that has permission to work with gas. Employees of such companies are required to provide documents about their work. The latter usually confirm that all actions with gas equipment were carried out in accordance with government standards and regulations.

It's better to use the first option. In any case, an employee of the service company must check that the stove in your apartment is connected correctly. Additionally, he will make notes in the registration certificate.

Installation and inspection of a gas stove by a gas service employee

It is worth paying special attention to the legality of the work. Any actions with gas carried out without concluding an agreement are considered illegal. This applies to private craftsmen or employees of official organizations who decide to earn extra money on the side. None of them will be able to provide documents for work. Therefore, replacing the slab and any changes will be considered illegal.

How a gas pipeline is built (connecting a gas line to a house)

With an approved project, you must contact a company that deals with similar work (necessarily with a state license). If the estimate drawn up by the company suits both parties, then an agreement is concluded to carry out the relevant work.

The contract must indicate that the final payment will be made only after all work has been completed and accepted by the official commission.

Upon completion of installation work, as-built production and technical documentation is drawn up, which must be approved by the commission. After successfully connecting the gas line to the house, you can immediately conclude an agreement for the installation of the equipment that will be connected (boiler, stove, etc.).

Read more: Sick leave after dismissal is paid within

Commissioning work must be carried out exclusively by gas specialists

Connection cost

The state is trying to control prices for gas connection services so that they are affordable to the majority of the population. Otherwise, this will lead to an increase in the number of illegally connected equipment. And this is a direct threat to security. And not only the owners who took the risk, but also their neighbors.

Installation of the stove by a qualified technician

Regulated tariffs for work are not established. We can only say that the cost of connecting a gas stove ranges from 1 to 3 thousand rubles. A number of factors influence the final price. Among them:

- the region where the customer lives;

- price list of the company the homeowner contacts;

- the difficulty of connecting in a particular house or apartment.

Work is paid upon completion. You should definitely ask the specialist for a receipt, which is also a document confirming the work officially carried out. If the installation was carried out by third-party specialists, calling a gas service employee to check the correct connection will also cost money.

How to make a calculation

A comfortable temperature in the apartment will be maintained if the heating system is installed correctly. To do this, it is necessary to accurately make all calculations, which will depend on the area of the room (S) and the boiler power (W) per 10 m². It is also necessary to take into account the climatic features of the region. For example, for the Moscow region the power density ranges from one to one and a half kW; in the northern regions - from one and a half to two kW; in the southern regions - from 0.7 to one kW.

The power of the heating boiler is calculated using the formula: cat. = SW beat / 10. This simple calculation will help you choose the boiler needed for your apartment.

Heating calculations also depend on the design and type of heating system. The best option for an apartment is a two-pipe system. It is more complex and more expensive than a single-pipe system, but the heating quality will be higher. All batteries, from the first to the last, will heat up evenly. The single-pipe system is only suitable for a small number of radiators.

Read more: Https lk oseest u filestoage download token

Features of connecting a gas stove

Depending on what type of housing requires installation, some nuances are highlighted in the first stages of the procedure.

In the apartment

After purchasing housing in an apartment building, the owner will need to enter into an agreement with the service company for the supply of gas. If all the papers are in order, the owner collects a package of documents and receives permission to install the stove. The list of papers includes the following.

- A purchase and sale agreement or other document fixing the right to own property.

- Technical passport of the apartment.

- If you have a previous contract for the maintenance of gas equipment, in this case a kitchen stove.

- If a meter is installed, a product passport will be required.

- Passport for the purchased new stove.

The collected papers are transferred to the gas service to obtain permission to operate the equipment. Additionally, employees provide instructions and provide documents for filling out under the new service agreement.

Scheme for connecting equipment and installing meters

In a private house

Depending on the homeowner’s decision, one of three options can be implemented:

- connection to a common pipeline supplying natural gas;

- using a stove powered by liquefied gas cylinders;

- lack of gas in the house.

The first option involves concluding a service agreement with a service company on the same principle as with apartment owners. In the second case, the equipment connection is carried out on your own or by ordering the services of specialized specialists.

Stove powered by a gas cylinder

Attention! The owner must take into account that when using gas under pressure, a lot will depend on the quality of the cylinders and the reliability of the connection. Many people prefer to carry out such work themselves, which often affects safety and reliability.

If possible, it is preferable to connect the gas supply of a private house to a common pipeline. Company employees will monitor compliance with standards. Thanks to this, the residents of the house will feel calmer than when ordering the services of third-party specialists, who cannot always provide sufficient guarantees when connecting.

Gas pressure standards

In addition to the percentage of methane contained in the gas, an important indicator of its quality is the pressure in the system. Gas pipeline systems are divided depending on the pressure level. Based on this, the following types of gas pipelines are known:

- With high pressure 1st grade (from 0.71 to 1.7 MPa).

- With high pressure 2 grades (from 0.4 to 0.7 MPa).

- With an average value (from 0.005 to 0.4 MPa).

- With low pressure (up to 0.004 MPa).

For your information

The low-pressure system is installed in residential buildings, catering establishments, boiler houses and household organizations. The medium and high pressure system is the power source for the distribution network of an entire city in the medium and low pressure network.

The gas line at the city level is the main one, as it supplies the entire settlement as a whole. It is designed as a large ring, semi-ring or beam. From there, gas is supplied to large enterprises, where the pressure regime is expected to be more than 0.8 MPa.

This is important to know: Compensation for housing and communal services for disabled people in 2020

Gas supply is carried out using different systems. It is chosen based on an analysis of pressure, degree of reduction and the basis for constructing the system (ring, dead-end or mixed), technical nuances and financial indicators. Features may relate to the volume, density structure of the gas level, the degree of safety of its supply system, construction and operational qualities.

The system can have the following types:

- 1-level , with gas supplied through a gas pipeline with the same pressure;

- 2-level , with 2 types of pressure;

- 3-level , with 3 pressures;

- multi-level , with 4 types of gas movement.

For separately located gas pipeline systems serving thermal industrial devices and boiler rooms, gas up to 1.3 MPa can be used if necessary. For an apartment building, as well as in places where a large number of people gather, the maximum pressure is 1.2 MPa.

Modern systems are a complex set of equipment consisting of mixed, dead-end or ring networks, which are characterized by high, medium and low pressure parameters. They are laid in cities and other populated areas, outside and in houses. They can also be located on the routes of stations and points that distribute and regulate gas, in communication systems, auto installations and mechanical equipment.

A trouble-free gas supply must be established, and a device must be available that turns off its supply in certain areas for repair work and eliminating the consequences of accidents.

Design in urban conditions is carried out on the basis of a general plan, regional plans, taking into account the development factor. The selected system (mixed, ring or dead-end) is based on calculations taking into account the structure and density of consumption, and should be the most financially efficient.

Materials

Most craftsmen provide materials for the work. However, if owners want to independently select the necessary consumables for connection, they can contact specialized stores. The list of necessary parts is discussed with the master in advance.

Typically, the list of consumables includes the following.

- Ball valve. Preferably brass, made for use in medium and low pressure liquefied and natural gas systems. Previously, spade valves were used when connecting slabs. Currently they do not meet established standards. After a long period of use, the part must be replaced.

Ball valve "Butterfly" - Hose made of flexible material.

The most common option is a rubber reinforced hose. - Pad . It is mainly included with the stove upon purchase and protects the equipment from small-caliber debris.

- Sealing material. Experts use either FUM sealing tape or Loktail 55 thread. The flax thread used previously is no longer as popular due to its lower reliability and durability.

FUM tape - Gas and adjustable wrenches.

- Screwdrivers.

Additionally, a soap solution is prepared to check the tightness. Medium saturation is enough. The liquid is applied with a brush to the mounting points to check the tightness of the system.

If the source of gas for the stove is a liquefied gas cylinder, a pressure stabilizing device must be installed. This is necessary to extend the life of the equipment. Plus this is one of the security measures.

Previously, it was common practice to connect a gas stove using a metal pipe. Now it is practically not used. Such a procedure requires more money, time and skills on the part of the master. The disadvantages of this method also play a role:

- Impossible. move the slab to another location due to the rigid fastening system.

- The pipes will more likely need to be made to order, which will be much more expensive.

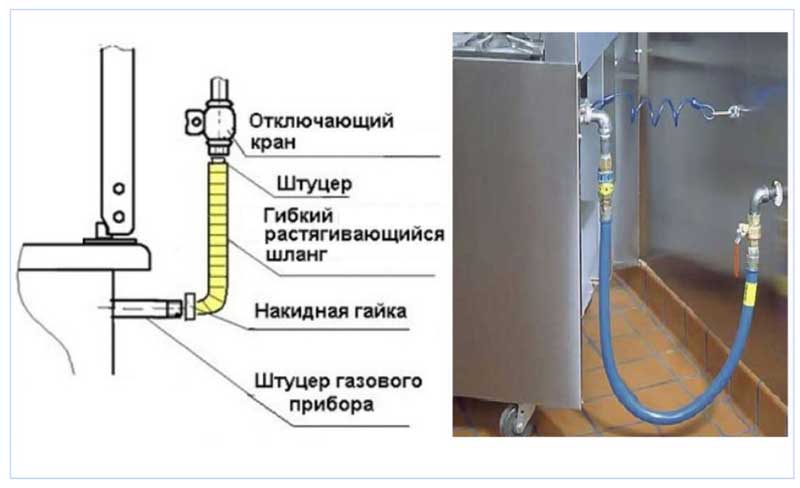

Hoses for gas stoves

Special attention is paid to the choice of hose. There are 3 types of products on the market , among which the owner or craftsman selects the most suitable one. According to regulations, the length of the flexible tube should not exceed 4 meters. The diameters of the fittings are standard ½″ and ¼″ inches, or the less common ⅜″ inches. The latter are connected through a conductor. Both ends of the hose are equipped with union nuts. Less often - a nut on one side and a thread on the other.

Table 1. Types of hoses for gas stoves and their properties.

| Hose type | Material | Dielectric properties | Life time | Advantages | Flaws |

| Rubber | Rubber, fabric seal for increased durability | Rubber is a dielectric; installing a gasket to protect against stray currents is not required | Up to 10 years | Low cost, due to which they are common in household use | Vulnerable to sudden temperature changes. They crack over time. Easily damaged by sharp objects |

| Rubber with metal braid | Vulcanized rubber or polymers, metal braid | Requires a gasket to eliminate stray current | Up to 10 years | More durable than rubber hoses, protected from mechanical stress | It is impossible to control the tightness of the rubber tube |

| Bellows | Stainless steel. Sometimes supplemented with a PVC polymer shell. The product has the shape of a corrugated hose | It is necessary to install a gasket to avoid stray currents | 25 years or more | Greatest resistance to mechanical stress. Resistant to pressure changes | High price compared to other items |

Bellows hose

Free replacement

Utility services in some regions provide the opportunity for certain categories of citizens to replace outdated and faulty gas equipment without paying a penny for it. The rules of procedure will need to be clarified in advance with the city gas service.

Who is eligible for the benefit?

Only certain categories of citizens can use the free stove replacement service. The benefit is obtained in the following cases:

- apartment owners receive subsidies from housing and communal services, are WWII veterans, have the titles of heroes of the USSR, socialist labor, the Russian Federation, or have received the Order of Glory;

- existing gas equipment is the property of the state, regardless of whether the apartment is municipal or owned by the tenant;

- the apartment is occupied by persons who have received it by right of queue for housing;

- in a family that needs to replace the stove, or a person living alone, the income is less than 1.15 of the subsistence level;

- single pensioners or families of pensioners who have reached retirement age and do not receive additional social assistance to pay for housing and communal services and living space.

In practice, there are very few such people, and replacement under the benefit is possible only if you have a package of documents confirming the right to receive such a service.

Free connection procedure

To replace a gas stove free of charge, you will need to provide a technical inspection certificate for the equipment. One copy remains with the gas service. The second one is received by the applicant, who transfers the document to the housing cooperative or economic development department. The examination is carried out by employees of the organization that controls the operation of gas appliances.

The paper indicates the service life, existing defects and malfunctions. Based on the conclusion received and the application for replacement, beneficiaries can receive a new gas stove for free. Additionally, the host provides identification.

Pensioners will also need:

- pensioner's ID;

- if necessary, a certificate in form 9 about registration at the place of residence.

Citizens with an income level below 1.15 of the subsistence minimum are prepared to submit:

- certificates of income of your personal and other family members for the last 3 months;

- if necessary, a certificate in form 9 about permanent registration at the place of residence.

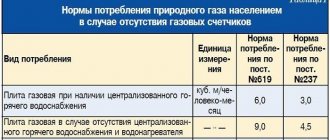

Rules for payment for gas supply

Gas is paid on the basis of information received from metering devices, and if they are not available, according to current standards. Relevant inspections are carried out at least once every six months, but not more than once every two months. If at least one of the requirements is not met, then the devices cannot be used as the basis for paying for gas. Then a recalculation is made based on general standards. If there is a metering device, subscribers pay a fee once a month until the 9th day of the next month after the previous one.

This is important to know: Decree 13 14: gasification of residential buildings

When using standards, factors such as:

- average standard per month;

- parameters of heated premises;

- the number of people living in them;

- level of home improvement;

- other information relevant to determining the amount of payment.

When calculating the total volume, the gas used is summed up for each type of consumption. If the subscriber did not inform about the circumstances due to which the volume of gas used changed, or unreliable data was presented, the volume of gas can be recalculated, but no more than six months before the previous check.

Safety regulations and rules

The requirements established for the connection process must be met regardless of who carries out the work. The specialist or the owner himself is obliged to take them into account. In this case, the risks will be minimal.

The list of standards includes the following items.

- The gas supply hose is always located in a visible place. There is unhindered access to it; nothing blocks the flexible tube. The part that supplies natural gas to the stove can be easily replaced by a specialist during a routine inspection.

- The flexible hose is manufactured in accordance with accepted standards; the cross-sectional size should not differ from the established one.

- Instead of paint, only self-adhesive paper is used to change the appearance of a rubber or metal gas line. Otherwise, the material, especially unbraided rubber, will quickly crack. This will break the tightness of the entire system.

- The flexible hose connects directly to the stove and the general gas supply system. The only exception is when the connection on the equipment or gas tap is made with an individual thread.

The hose is screwed to the tap without adapters - Installation of the unit is carried out only with the use of tools and materials designed specifically for working with natural or liquefied gas.

- Before carrying out work, the specialist stops the gas supply when it comes from the common riser, and be sure to notify all residents of the apartment about the installation of gas equipment.

- If the gas source is not shut off with a special tap and the work is not carried out immediately, the end of the supply pipe is plugged with a wine stopper or a wet thick cloth to stop the gas supply. When it is necessary to shut off the gas for several days, gas service employees install a special plug.

We connect the gas stove ourselves

Carrying out work on your own is permissible in extreme cases, provided that the owner of the house has the appropriate knowledge and strictly adheres to safety rules on his part. The step-by-step process can be described as follows.

Step 1. Shut off the gas supply to the stove using the existing ball or petal valve.

Closed gas valve

Step 2. Check the fuel supply to the burners. If, when you try to light the gas, the fire does not appear, the stove can be turned off.

Hardware check of gas supply to burners

Step 3. Unscrew the hose from the stove and the gas supply tap.

Disconnecting the hose from lowering

Step 4. If necessary, replace the gas valve with a new one.

- Open windows or vents, or use special ventilation equipment.

- Close the new tap by turning the lever and wind a sealing thread or tape onto the external thread.

- Using an adjustable wrench, unscrew the old part from the gas supply system. Clean the threads on the pipe and screw a new closed valve to it. If the lowering pipe is equipped with an external thread, the sealant is wound onto it, and the valve is subsequently connected using a pipe with an internal thread.

- Check the connections for leaks using special equipment or the “old-fashioned” method. A strong soap solution is applied to the joint. If bubbles appear, the work must be redone and checked again for leaks. You will have to work especially carefully with FUM tape, since it often breaks under the influence of the thread.

Step 5. Place the kitchen stove in the unit or in a separate place where it will be located in the future. Leave the distance to the wall in accordance with the requirements in the technical data sheet of the equipment. If necessary, level the legs using a building level.

Connecting a stove built into a kitchen unit

Step 6. Check the presence of gaskets in the flexible hose kit. If there is an external thread, seal it with thread or FUM tape.

Winding-FUM-tape

Step 7. If the threads on the plate do not meet the standards, attach the adapter, sealing the joints.

Hose gasket

When using a bellows or rubber hose with a metal braid, use couplings made of dielectric material to protect against stray currents. The latter appear if the stove uses electric ignition, or the hob or oven runs on electricity.

Step 8. Screw on the hose using a wrench. It is important to carry out the work carefully. Otherwise, gas will enter the room from the supply system. This occurs due to the fastening being too tight, damaging the sealant, or when the connection is loose.

Gas hose connection diagram

Under no circumstances should the hose be twisted or bent too much. It is ideal when it is not tense and hangs freely.

Step 9. Conduct a final tightness check of the entire connection.

Checking the tightness with a soap solution

Any homeowner should know the basic principles of proper connection. Even if you do not install gas equipment yourself, this will allow you to monitor the work of invited specialists. Safety depends not only on the professional. You can connect a kitchen stove with your own hands only if you have sufficient experience and skills.

Basic regulatory documents

Requirements for gas boiler houses are given in the following regulatory documents in force in 2020:

- Instructions for the placement of thermal units intended for heating and hot water supply of single-family or semi-detached residential buildings (MDS 41-2.2000) (is advisory in nature)

Let us highlight the most important requirements (point by point) that must be met when designing and building a gas boiler room in a house, as well as when designing the route for laying a gas pipeline:

According to SP62.13330.2011:

pp. 5.1.6* Gas pipeline entries into buildings should be provided directly into the room in which gas-using equipment is installed, or into an adjacent room connected by an open opening.

It is allowed to provide for gas pipelines entering apartment kitchens through loggias and balconies, provided that there are no detachable connections on the gas pipelines and access is provided for their inspection.

It is not allowed to enter gas pipelines into the premises of the basement and ground floors of buildings, except for the introduction of natural gas pipelines into single-family and semi-detached houses and industrial buildings, in which the introduction is determined by the production technology.

pp. 5.2.1 Gas pipelines should be laid at a depth of at least 0.8 m to the top of the gas pipeline, casing or ballasting device, except in specified cases. In those places where traffic and agricultural machinery are not expected, the depth of laying steel gas pipelines must be at least 0.6 m.

pp. 5.2.2 The vertical distance (clear) between the gas pipeline (case) and underground utility networks and structures at their intersections is recommended to be taken in accordance with Appendix B* SP62.13330.2011.

According to Appendix B*, when laying a gas pipeline underground (gas pressure up to 0.005 MPa) and the most common communications on the land plot of a private house:

- Vertically (at intersection) with water supply and sewerage - at least 0.2 m in clear space (between pipe walls)

- Horizontally (parallel) with water supply and sewerage - at least 1 m

- Horizontally (in parallel) with power cables up to 35 kV - at least 1 m (when installing a protective wall, it can be reduced to 0.5 m)

According to SP 42-101-2003 it is recommended:

pp. 6.17 ....In the room where gas-fired heating equipment is installed, it is allowed to use window openings as easily removable enclosing structures, the glazing of which must be carried out according to the condition: the area of individual glass must be at least 0.8 m 2 with a glass thickness of 3 mm, 1.0 m 2 - at 4 mm and 1.5 m 2 - at 5 mm .

pp. 6.18 It is recommended that the following conditions be observed for rooms intended for the installation of gas-fired heating equipment:

- height of at least 2.5 m ( 2 m - with equipment power less than 60 kW);

— natural ventilation at the rate of: exhaust — in the amount of 3 air exchanges per hour ; inflow - in the volume of exhaust and additional air for gas combustion. For equipment with a power of St. 60 kW the dimensions of exhaust and supply devices are determined by calculation;

- window openings with a glazing area at the rate of 0.03 m 2 per 1 m 3 of room volume and structures enclosing from adjacent rooms with a fire resistance rating of at least REI 45 - when installing equipment with a capacity of over 60 kW or placing the equipment in the basement of the building, regardless of its power;

- exit directly to the outside - for premises on the ground and basement floors of single-apartment and semi-detached residential buildings when installing equipment with a capacity of St. 150 kW in accordance with the requirements of MDS 41-2

pp. 6.19 In residential buildings, it is recommended to install household gas stoves in kitchens that meet the requirements of manufacturers’ instructions for installing gas stoves, including in kitchens with sloping ceilings, having a room height in the middle part of at least 2 m , while the installation of the stoves should be be provided in that part of the kitchen where the height is at least 2.2 m.

pp. 6.23 In the absence of requirements in the manufacturer’s passports or instructions, gas-using equipment is installed based on the conditions of ease of installation, operation and repair, and it is recommended to provide for the installation of:

gas stove:

- near a wall made of fireproof materials at a distance of at least 6 cm from the wall (including the side wall). It is allowed to install the slab against walls made of fire-resistant and combustible materials, insulated with non-combustible materials (roofing steel on an asbestos sheet with a thickness of at least 3 mm, plaster, etc.), at a distance of at least 7 cm from the walls. Wall insulation is provided from the floor and must extend beyond the dimensions of the slab by 10 cm on each side and at least 80 cm on top;

wall-mounted gas-using equipment for heating and hot water supply:

- on walls made of fireproof materials at a distance of at least 2 cm from the wall (including from the side wall);

- on walls made of fire-resistant and combustible materials, insulated with non-combustible materials ( roofing steel on an asbestos sheet with a thickness of at least 3 mm, plaster, etc. ), at a distance of at least 3 cm from the wall (including from the side wall).

This is important to know: Heating system inspection report: sample

The insulation should protrude beyond the dimensions of the equipment body by 10 cm and 70 cm from above. The horizontal clear distance from the protruding parts of this equipment to the household stove should be at least 10 cm.

When installing the above equipment on a wooden floor, the latter must be insulated with fireproof materials, providing a fire resistance limit of at least 0.75 hours. The floor insulation must protrude 10 cm beyond the dimensions of the equipment body.

6.24 The clear distance from protruding parts of gas-using equipment in passage areas must be at least 1.0 m.

According to MDS 41-2.2000 it is recommended:

clause 5.1 When placing a gas stove, instantaneous water heater for hot water supply and a heating unit for heating with a power of up to 60 kW in the kitchen, the kitchen room must meet the following requirements:

— the volume of the room is at least 15 m3 plus 0.2 m3 per 1 kW of power of the thermal unit for heating;

pp. 5.2 When placing thermal units with a total power of up to 150 kW in a separate room located on any floor of a residential building, the room must meet the following requirements:

— the volume and area of the room are designed based on the conditions for convenient maintenance of thermal units and auxiliary equipment, but not less than 15 m 3 ;